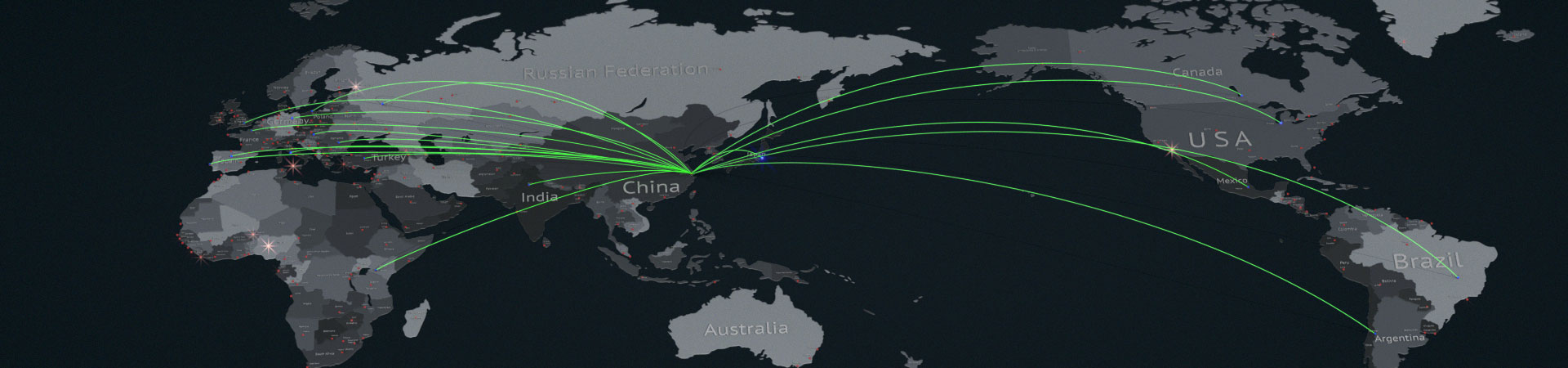

Global Tooling Resources

Your Partner in China – Adding Value to your Manufacturing Product Lifecycle

Global Tooling Resources (GTR) is an innovative company that is staffed with highly skilled engineering talents serving clients globally in various industries as a worldwide source of Engineering and Supply Chain Management Services. GTR specializes in different operations related to metal stamping including Formability and Springback Simulation, Tool & Die Process Layout, Tooling Design, Research & Development, Material Supply, Global Product Sourcing, and On-site Program Management. In terms of material, GTR puts focuses on Ultra High Strength Steel and Aluminum to provide Light Weight Solutions to our clients. With high efficiency at a lower cost base, GTR can assist its clients to reduce costs and add values in every stage of the clients’ Manufacturing Product Lifecycle.

Case Studies

A major Tier One automotive supplier in North America was launching a program with a German OEM in Mexico and received kick-off on several large-scale engineering changes in mid-Dec 2015. The Tier One had to complete…

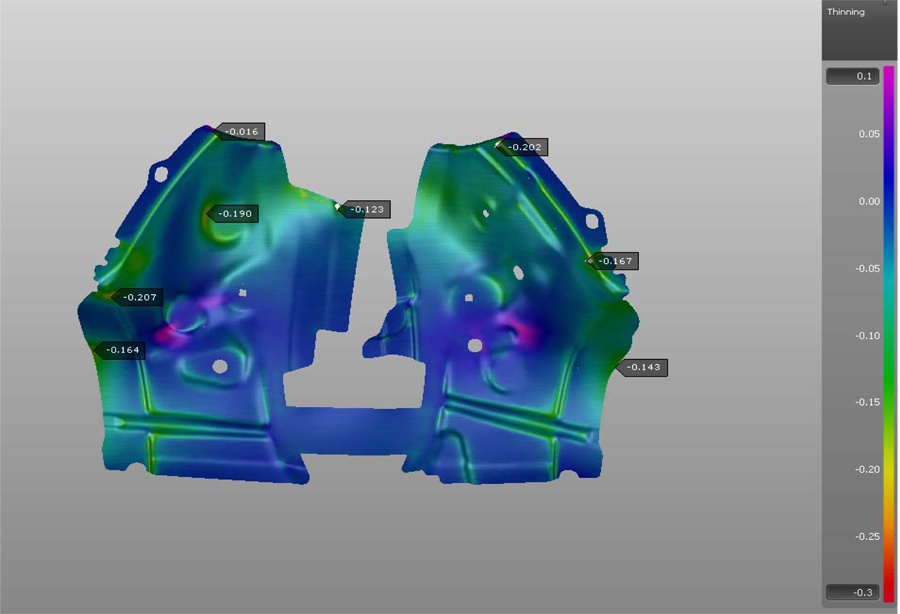

A renowned global automotive tooling company was working on a die project for a German OEM in early 2015. GTR was contracted by the tool shop to conduct a formability and spring back analysis on an rather unique material for this project…

GTR received an inquiry from affiliated companies NMC and NMM in North America for high strength steel. The inquiries came from one of the world’s largest automotive Tier One supplier who was urgently looking for tryout material to be shipped…

Our client, a major automotive Tier One supplier in Canada, initiated a cost reduction program in 2015 to reduce their overall landed cost of tooling coming from China. Our client sources a substantial amount of tooling…

Why Choose GTR

“We see ourselves as an extension of your company in China, taking care of all the details you would if you were here.”

The Evolution of Steel: AHSS

The evolving use of Advanced High Strength Steels continues to grow in application – especially in the automotive industry.

These state-of-the-art steel types are improving the safety, fuel economy, and all-around performance of vehicles on the road.

Advanced high-strength steels are multiphase steels that contain martensite, bainite, and/or retained austenite in amounts sufficient to produce unique mechanical properties (transformation hardening).

This high strength and high formability combination of AHSS allows engineers to meet requirements for safety, durability, efficiency, emissions, manufacturability, and quality at a lower cost. These new generation of steel grades have a bright future – and Global Tooling Resources wants you to take part.