Case Study – Reduction in Time and Money While Maintaining Quality

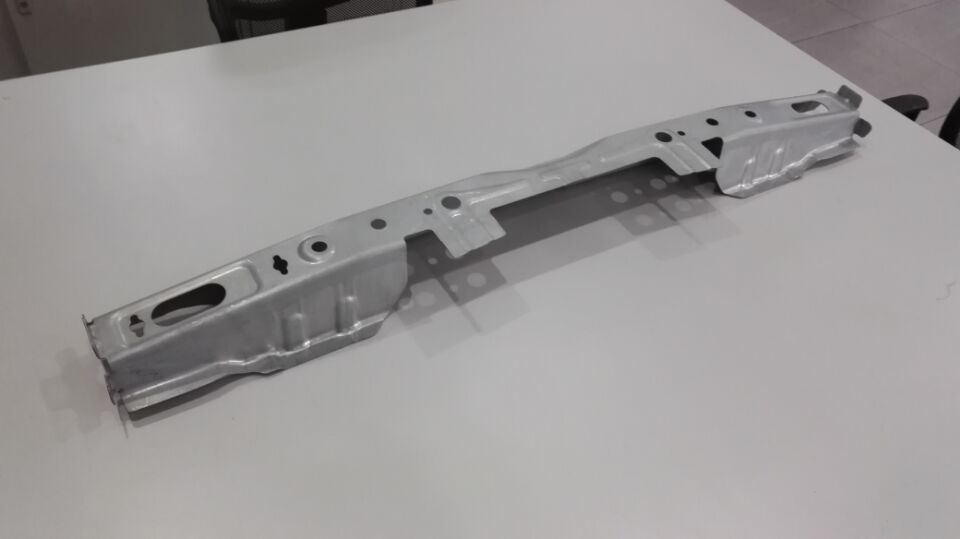

A renowned global automotive tooling company was working on a die project for a German OEM in early 2015.

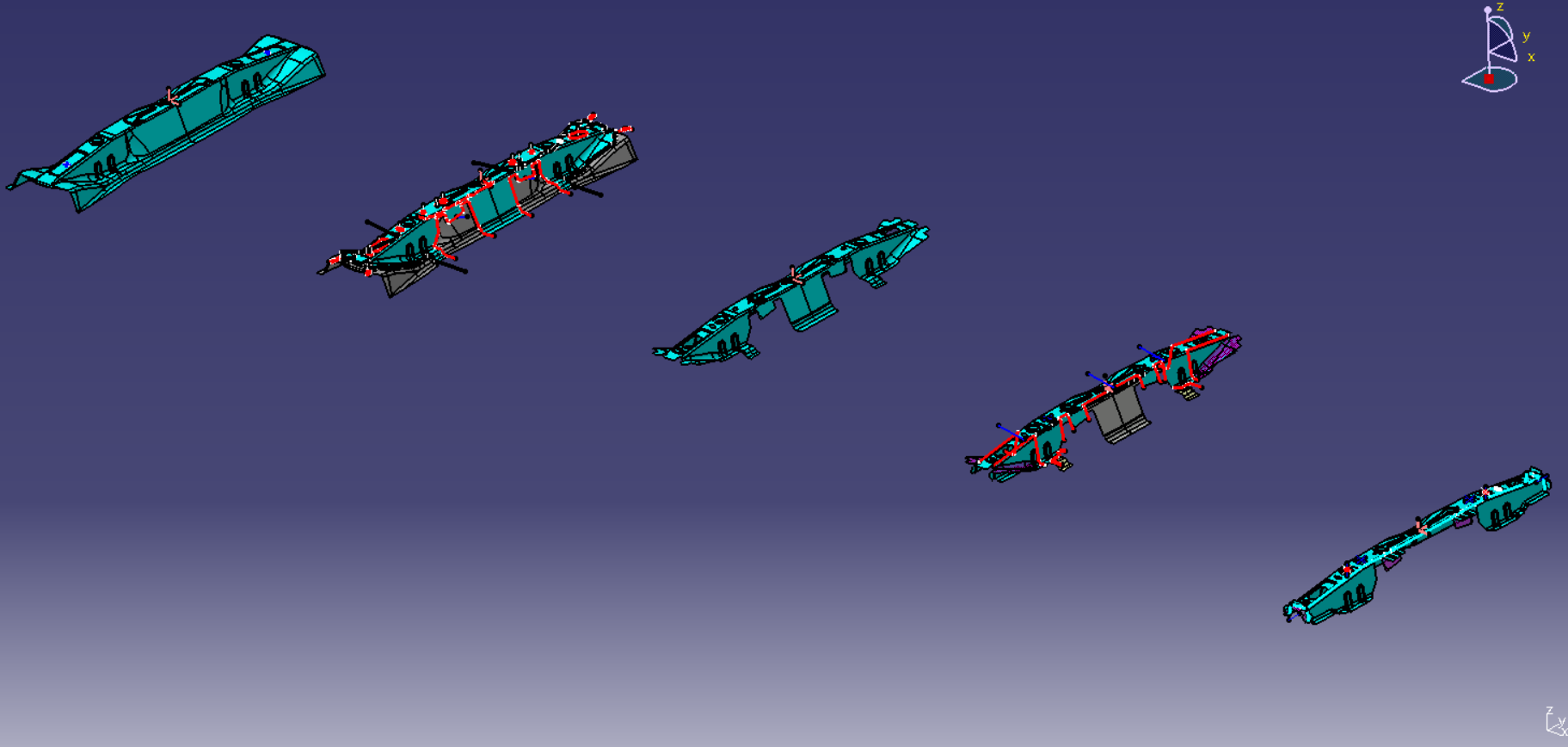

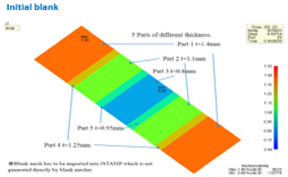

GTR was contracted by the tool shop to conduct a formability and spring back analysis on a rather unique material for this project. The material was a Taylor Rolled blank which consisted of three different thicknesses of high strength steel. Unlike Taylor Welded blanks, there were no seams in the transitions from one material thickness to the other. For that reason, two more material thicknesses were used as the transitions. With five different material thicknesses in one single blank, the tool shop needed to have very accurate predictions of how the steel would react in order to properly engineer their die process and design.

Global Tooling Resources went ahead and conducted the studies by carefully examining the part configuration and applying the best software for formability and spring back analyses. By combining the power of computer simulation and our rich experience in tooling, GTR was able to apply the correct amount of compensations to the part at each iteration of the simulation process to achieve green status. The end result was a high degree of predictability delivered to the tool shop in terms of part dimensional conformance for the die development process with this Taylor Rolled blanks. The pass rate on the first hit during die tryout was 92%. And after only three quality loops, the tool shop was able to bring the part to 100% quality level. In conclusion, GTR’s die simulation analysis reduced the clients’ tooling tryout time and money while achieving excellent part quality.